Onlookers! What attracts FAW Audi, Geely Automobile and others to come to Longquan to test products

"This is a new product that we have just put into mass production. The thermal expansion valve for Changan Automobile's Uno model has shortened our research and development cycle by two months from project initiation to mass production." On December 12, At Zhejiang Xinjin Air Conditioning Equipment Co., Ltd., deputy general manager of technology Ye Fangping told reporters: "This is all thanks to the strong support of the technology innovation service platform for the automotive air conditioning industry."

Xinjin company production workshop

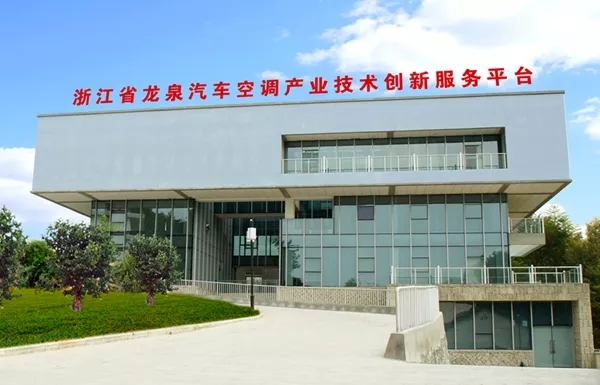

Zhejiang Longquan Automobile Air-conditioning Industry Technology Innovation Service Platform was completed and put into operation in November 2013. It is an innovation carrier of Longquan City Government’s investment, public welfare and marketization. It has invested 41 million yuan in construction funds and purchased direct reading spectrometers (US ), coordinate measuring instrument (Sweden), automobile air-conditioning comprehensive performance table and other internationally advanced and domestic leading inspection and testing equipment, providing inspection, research and development, consulting, exhibition, training and other "shop small two" public Innovative services.

Innovative service platform

“It’s not easy to shorten the R&D cycle by two months. One is that our project preparations are ahead, and the other is that the innovative service platform is geographically close, and data can be obtained at any time, and the process can be improved at any time. Moreover, the staff also work overtime to support our local area. Enterprise project testing." Ye Fangping told reporters that the platform not only shortens the product development cycle, but also provides technical support for the company's entry into the main engine market. Currently, the company supports more than 10 projects with expansion valves for Geely, Changan, and Guangzhou Automobile.

Expansion valve products

"With the gradual increase in the volume of new products in the domestic host market, our output value this year is expected to increase by 15% year-on-year to around 200 million yuan. The growth trend is obvious. Among them, more than 50% will be matched by host manufacturers, and it is expected to reach more than 20% next year. Increase."

Xinjin Company

At the Longquan Automobile Air-conditioning Industry Technology Innovation Service Platform Comprehensive Performance Testing Laboratory, the deputy director of the platform, Jun Ye, said: “Many testing equipment easily cost millions, some even tens of millions, and this comprehensive performance test bench reaches more than 10 million yuan. It is difficult for all equipment companies to purchase independently. On the one hand, the investment in fixed assets accounts for a large proportion, which affects the operation of the enterprise. On the other hand, the requirements for talents are also high."

Industrial platform comprehensive performance testing console

It is understood that, like Zhejiang Xinjin Air Conditioning Equipment Co., Ltd., more than 100 companies rely on industrial innovation platforms for product development and product testing. This year, the platform tested more than 2,600 products for automobile air-conditioning companies in and outside the city, including more than 60 companies outside the province, including FAW Audi, Geely Automobile, and GAC Trumpchi. The platform promotes industrial transformation and upgrading, and leads the innovation-driven development of Longquan's automotive air-conditioning parts industry. In 2016, the output value of the automotive air-conditioning parts industry was 8.5 billion, accounting for nearly 40% of the city's industrial output value.

Industry Platform Noise Laboratory

Over the past four years, with the continuous investment of various testing equipment, the platform has purchased more than 40 sets of advanced testing equipment at home and abroad, with a total equipment value of 36 million yuan and 157 inspectable items, including academicians. With the intellectual resources of more than 160 industry experts, the inspection and testing of the center has radiated from Longquan to the whole country. With the help of experts from Zhejiang University and joint leading enterprises, it has developed 93 new materials, new processes, new products, 36 technical achievements promotion, and 27 provincial and municipal scientific research projects approved. The platform testing center also passed the on-site review by the CNAS expert group in October.

At present, the platform expansion project of Longquan City Industrial Innovation Base and National Automobile Air Conditioning Inspection Center is accelerating, and the main project is about to be completed. The project is a key project in Longquan City, with an investment of 91.33 million yuan in the first phase, including a testing center, R&D and design center and related supporting projects. The platform will be built into an industrial innovation service complex, and will play a new role and make new contributions for Longquan Automotive Air Conditioning to become China's automotive air conditioning intelligent manufacturing base, the world's automotive air conditioning distribution center, and the new energy automotive air conditioning research and development highland.